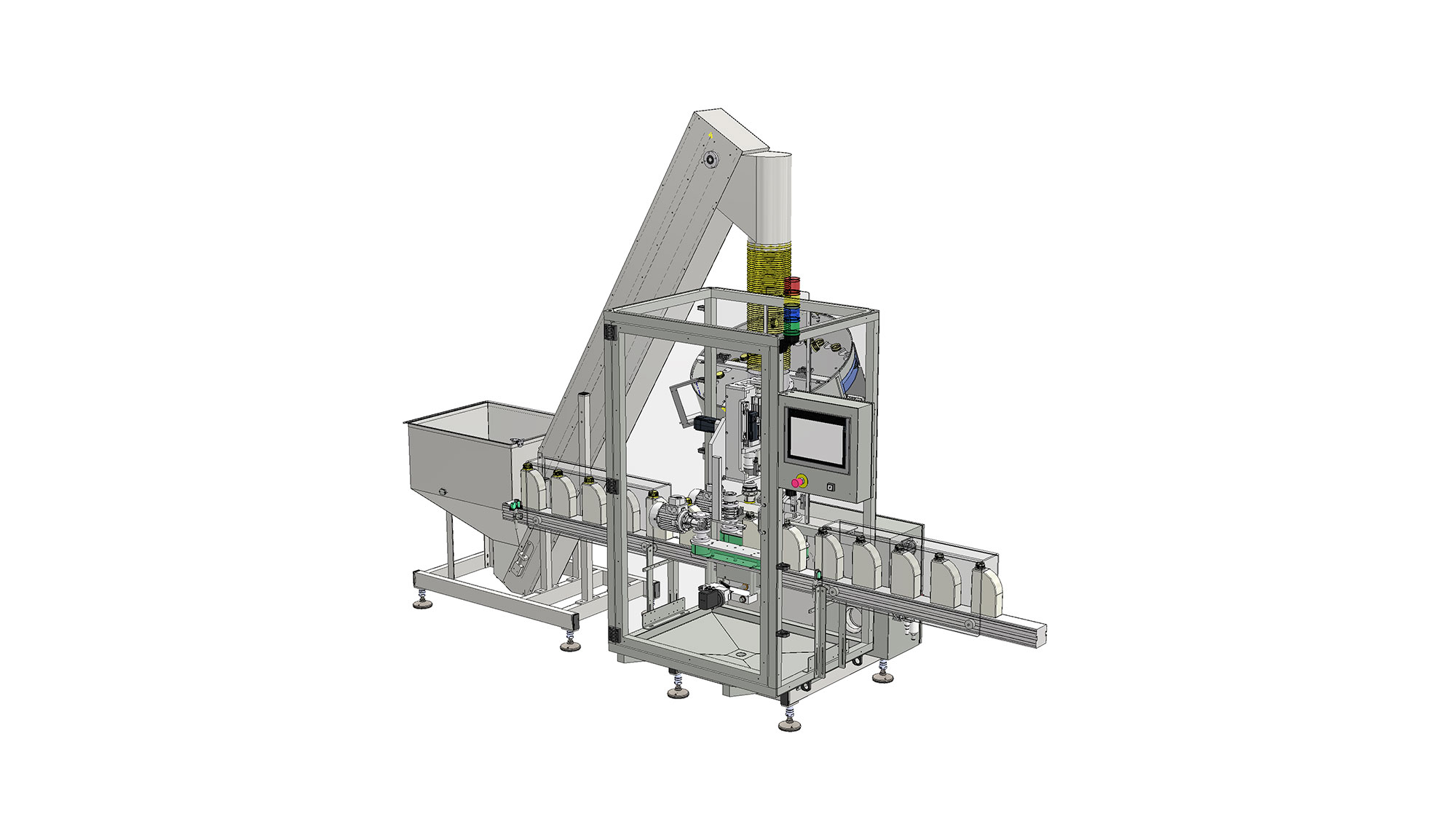

Pacing Capper™

Flexible, robust and reliable are the properties best describing the Pacing Capper™. Our well-developed method of pacing each package into capping position has given this machine its name. Pacing Capper™ can produce up to 45 packages per minute.

Flexible

Can handle most caps and packages

Pacing Capper™ can cap on many different conveyor heights/widths and package/cap sizes. It has a range of small 50 ml bottles to 35-liter jerry cans with small and large caps. The machine can also handle both coloured and transparent glass and plastic packages.

Read more about it in the data sheet.

Accessible

Easy and quick access to all machine parts

All parts are easily accessible in the open construction for future service and maintenance.

Changeover between different caps

A simple exchange of format parts

Format parts for the cap are designed so that they can be switched out in a plug-and-play manner to quickly and easily adjust the machine between different cap models.

Changeover between different packages

At the press of a button

When switching between packages there is no need for format parts. The machine will store information about the package dimensions in its software and will perform a swift and automatic changeover between different package models.

Operator panel

Operator panel

Gives the operator easy and effective access to the machine

The touch panel is clear and pedagogical in its design, all to make operating it easy for all users both when it comes to daily use as well as e.g. setting up new recipe parameters.

Sorting unit

Sorts all caps

Two nozzles are used to blow away caps that are oriented the wrong way in the cap compartments. This ensures that all caps delivered from the cap sorting unit are oriented the correct way for capping.

Cap ejector

Cap ejector

Positions the cap in the gripper

Every sorted cap is ejected into the gripper before capping. This operation provides control over the cap delivery step.

Gripper

Gripper

Robust and repeatable servo capping

Once the gripper has received the cap from the cap deliverer, the gripper will pivot to the neck of the package and tighten or press on the cap. The force of the servo-controlled capping is adjustable and repeatable with high accuracy. This operation provides control over the tightening quality.

Cap control

Will not release any non-capped packages

Packages which have not been correctly capped will pause the machine. There is also a possibility of adding a reject station for these packages to avoid any halts in production.

Machine orientation is available in two different versions with infeed from either the left or the right. Layout drawing is available for download and pictures showing different options can be seen in the data sheet.

Pacing Capper™ is well-suited for installation in many different environments, e.g. food & beverage, chemical, petro-chemical, pharmaceutical, and ATEX environments.