Filling machine Trefill Compact™

Trefill Compact™ is the most compact filling machine in the Trepak filling machine family Trefill™. Trefill Compact™ is suitable if you are looking for a machine that can produce up to 50 packages per minute and can be equipped with 1-3 filling nozzles. In this machine, it is possible to use different dosing techniques. In the default version, the filling product is dosed with pumps which feed the product from a gravitating balance tank. Alternatively, the machine can be equipped with a flow meter where the product is fed from a pressure tank. Both techniques provide high accuracy and capacity. The machine is available in an ATEX version and can also handle e.g. viscous products.

- Capacity: ≤50 packages/minute

- Package volume: 100 mL – 25 L

- Package height: max. 500 mm

- Number of filling nozzles: 1-3

Pump with balance tank

The filling product is fed into the balance tank and dosed out to the filling nozzles via individual pumps. The pumps achieve high filling precision and handle both viscous and free-flowing products. The pumps are gentle on the product and can therefore handle products containing particles. The customer’s product determines which type of pump is chosen for each project. Trefill Compact™ with pump dosing is prepared with a flushing system.

User-friendly package handling

Quick adjustment

Our package handling is easily adjustable with a few levers on the operator’s side. When repositioning the rails, the packages are centered depthwise below the filling nozzles. To help the operator, clear and easy-to-read scales provide high repeatability.

Format change with high flexibility

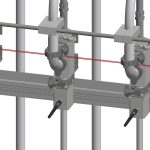

Quick changeover with high repeatability

When changing package type, the filling tubes need to be moved to the correct position above the packages that have been fed into the filling machine. This is easily done with a knob without any additional tools. If you use different filling tube sizes, these are also easily changed without tools.

Self-gravitating balance tank

Creates the right conditions for accuracy and capacity

A balance tank maintains an even liquid level to give the dosing pumps the same conditions fill after fill. This means that the pump filling maintains high accuracy. The technology requires that the product has a viscosity that allows the product to flow towards the pumps. The balance vessel is placed low and equipped with a rinsing system for rinsing between products. The balance tank is available in both stainless steel and plastic to enable handling of different product types.

Coarse and fine filling

Provides high acccuracy and avoids splashing

Coarse and fine filling is performed by controlling the pump speed which controls the flow for each filling tube/nozzle. The different modes of coarse/fine filling are used to optimize the filling sequence for each unique filling product. This system provides a high filling accuracy and can handle both easy-flowing and viscous filling products.

Filling nozzles

The right tubes for your products

Trepak’s filling tubes/nozzles are available in many different sizes and materials. The most common type is smooth acid-resistant pipes with a high finish. If you are going to fill more aggressive liquids, there are also plastic filling tubes that handle this. We have filling tubes/nozzles for both bottom filling and top filling. The product’s characteristics determine which filling tube/nozzle is the best fit. The position of the filling tubes is monitored and this provides extra security if a package would be incorrect or incorrectly fed into the filling machine. The lower part of the filling nozzle can be replaced so that the filling can be done as optimally as possible.

Capacity

Calculations helping you to choose the right machine

We have developed calculation models* for the production outcome. This means that you can trust that your new filling machine meets the requirements set at the start of the project.

*In the calculation model, we start from the properties of water and this gives us a starting value in our quotation documents. This means that quoted specifications can be guaranteed.

Operator panel

User-friendly interface increases efficiency

Trepak’s clear touch panel simplifies tasks for all users, whether it’s daily operations or setting up new recipe parameters for different packages or product types.

Service friendly

Easy and quick access to all machine parts

For future service and maintenance of the machine, all parts are easily accessible in the open construction. Balance tank and pumps sit on their own removable stand, which increases accessibility. The doors are large and do not obstruct work in the machine.

Drip tray

No splashing on the packages

Trepak’s filling machines are designed to avoid product residues ending up on the packages. As an extra guarantee, we have a drip tray in the machine that catches any residue that sits on the outside of the filling pipes, for example after bottom filling. The drip tray is equipped with a spill hose.

Weight adjustment with a control scale

Extra feedback to maintain the correct weight over time

The filling machine is prepared for feedback from a control scale. If the weight changes due to the product changing, the deviation is automatically adjusted during operation. Each filling tube/nozzle can be adjusted individually. We collaborate with different scale suppliers, e.g. Teltek.

Accuracy

Correct amount in the package

Trepak guarantees that our machines meet the EU requirements for filling accuracy.

Allowed negative deviation

Of a batch of finished packages, only a small percentage may lie below a certain tolerance limit and none may lie below the double tolerance limit. The tolerances for different package sizes are defined as the allowed negative deviations in the table.

Tillåten negativ avvikelse.pdf (Allowed negative deviation, original pdf in Swedish) (ri.se)